TORAYFAN™ NO Non-Oriented Polypropylene Film

A non-oriented polypropylene (CPP) film that can be used as packaging sealant. For use in various applications including retort pouches.

Packaging

IT/Industry

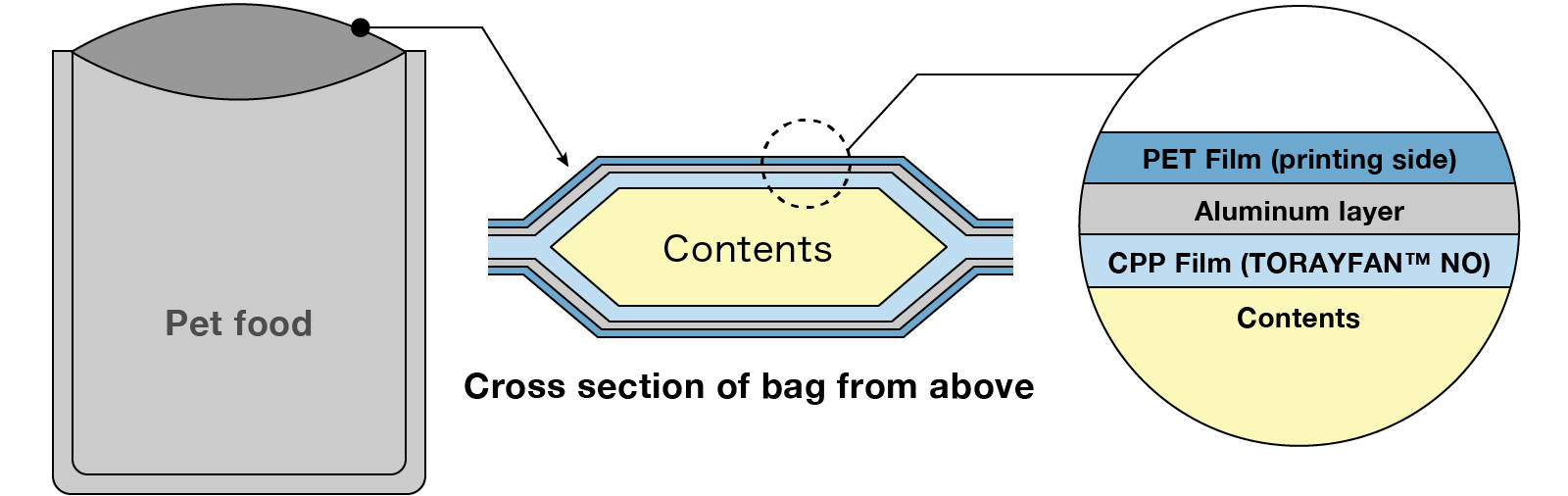

TORAYFAN™ NO is a non-oriented polypropylene film that can be used in packaging-sealant applications. Used for applications such as the inside surface of retort pouches (CPP for retort use). Film for other applications is also available, including deposition, anti-static, general lamination, etc.

- Excellent sealing and durability protects the contents from impacts and drops.

- Harmless and low-odor, excellent for food hygiene.

- Suitable for retort processing up to 135°C (depending on type).

- Large-size pouches are also available.

- Retort, deposition, anti-static, general lamination, etc. can be selected to suit the application.

Click here for IT and industrial base material films

Features

- Suitable for DL (dry lamination)

- Selectable the performance type (tensile strength, high transparency, general purpose/semi-retort/high-retort, etc.)

The polypropylene layer between the aluminum layer and the contents prevents changes to the taste and smell.

Example Applications

- Boiling/retort

- Snacks

- Toiletries

- Wet goods

- Miscellaneous items

- Deep drawing

Boil/retort package (image for illustrative purposes)

Technical Information

Properties Table *Values are representative/measured values and are not guaranteed.

| Item | Reference Standards | Unit | TORAYFAN™ NO | |||||

|---|---|---|---|---|---|---|---|---|

| ZK207 | ZK500 | ZK99S | ZK100 | 3951 | ||||

| Features | Good Bag-Break Strength | Excellent Bag-Break Strength | Heat Sealability Strength | High Transparency | Semi-Retort | |||

| Heat Resistance | Up to 135°C | Up to 120°C | ||||||

| Heat Sealability Strength | High | Medium | High | Medium | High | |||

| Bag Break Strength | High | Very high | Medium | Medium | Low | |||

| Transparency | Medium | Medium | Medium | High | High | |||

| Fold Whitening | Medium | High | Medium | High | High | |||

| Orange-Peel Texture | Medium | High | Medium | High | High | |||

| FDA 21CFR 177.1520 Compliant | Yes | - | ||||||

| EU directive 10/2011/EC Compliant | Yes | - | ||||||

| Thickness Range | Micron | 50-100 | 30-100 | |||||

| Corona-Treated Surface | Inside | |||||||

| Relative Density | 0.9 | |||||||

| Thickness | Micron | 70 | 60 | |||||

| Tensile Strength | MD TD |

JIS K7127 | MPa | 50 40 |

52 40 |

48 38 |

51 37 |

48 35 |

| Tensile Elongation | MD TD |

JIS K7127 | % | 750 900 |

760 880 |

740 810 |

760 860 |

700 830 |

| Young's Modulus | MD TD |

JIS K7127 | MPa | 630 520 |

480 350 |

600 530 |

670 570 |

500 460 |

| Haze | JIS K7361 | % | 44 | 51 | 57 | 12 | 6 | |

| Friction Coefficient (EC/n-EC) |

Static Kinetic |

JIS K7125 | 0.9 0.8 |

1.1 1.0 |

1.1 0.9 |

0.8 0.8 |

0.2 0.2 |

|

| Surface Roughness | EC surface Non-EC surface |

Micron | 0.18 0.18 |

0.24 0.24 |

0.20 0.20 |

0.15 0.15 |

0.20 0.20 |

|

| Blocking Shear Force (n-EC/n-EC) |

80°C | N/12 cm2 | 10 | 20 | 13 | 20 | - | |

| Wetting Tension | EC surface | JIS K6768 | mN/m | 40 | 40 | 40 | 40 | 40 |

| Heat Sealability Strength | Initial MD Initial TD |

N/15 mm | 73 71 |

66 70 |

76 71 |

71 66 |

81 78 |

|

| Post-retort MD Post-retort TD |

67 67 |

64 65 |

77 69 |

62 60 |

80 74 |

|||

- Heat Sealability Strength Retort condition : 130℃(266F) × 30min