CF Film Easy-Peel Film for Packaging

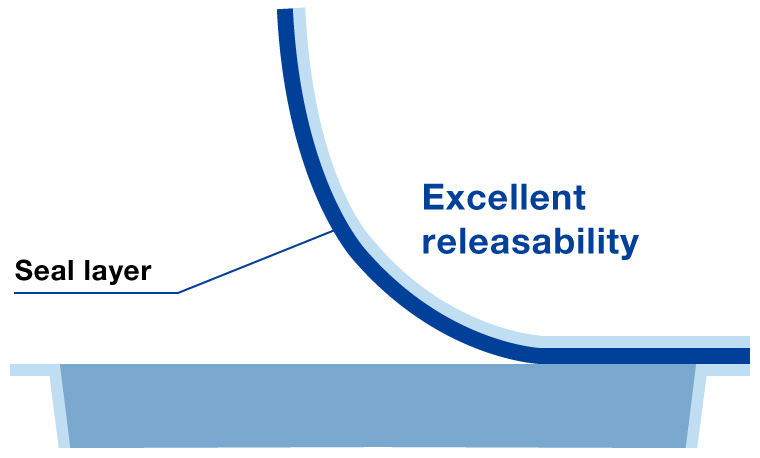

This non-oriented co-extruded multi-layer film has the "easy peelability" required for lid seals, etc.

Packaging

CF Film is a non-oriented, co-extruded multi-layer film with the "easy peelability" required for lid seals, etc. A wide range of products are available.

- Can be used as packaging in a wide range of applications, including jellies and other dessert cups, rice, medical equipment, meat, and beverage lids.

- Films are primarily PP (polypropylene) and PE (polyethylene) based and performance differs depending on the series. Select the film to suit your application.

[PP based]

• 9501 Series

PP-based cohesive--peel-type peelable film. Suitable for dry lamination, can be used for boiling and semi-retort (120°C). 9501K2 also has anti-fogging capability.

[PE based]

• 7601 Series

PE-based cohesive-peel type. Types suitable for dry lamination and polyethylene extrusion lamination (including the 7603 and 7601E Series) are available.

• 7603B, 7603MS

Interface-peel-type peelable films compatible with a variety of adherends. The 7603MS in particular can be used in a wide range of temperatures, and has excellent low-temperature strength retention and blocking resistance.

• 7601E Series

Cohesive-peel type suited for use in PE-coated paper containers. Soft peeling with a clean release that does not tear the paper from the container, and an excellent seal. It can also be used for film-to-film packaging.

Features

- Easy peel

- Peel strength

- Suitable for DL (dry lamination) (depending on type)

Example Applications

- Boiling/retort

- Toiletries

- Cover film for cups

- Wet goods

Lid for plastic container for jelly, etc. (image for illustrative purposes)

Technical Information

Properties Table *Values are representative/measured values and are not guaranteed.

| Item | Reference Standards | Unit | CF Film (PP Based) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 9501A | 9501C | 9501E | 9501F | 9501G | 9501H | CX8 | 9501K2 | ||||

| Peel Type | Cohesive | ||||||||||

| Peel Strength N/15 mm (PP Sheet) |

Weak 11 |

Medium to strong 18 |

Medium 14 |

Weak 11 |

Medium 16 |

Strong 22 |

Strong 21 |

Medium 20 |

|||

| Adherend | PP, PE | ||||||||||

| Heat Resistance | Up to 120°C | ||||||||||

| Suitable for Retort | Yes (9501F, G, and H have excellent oil resistance when retorted) | ||||||||||

| Suitable for DL | Yes | ||||||||||

| Suitable for EL | No | ||||||||||

| FDA 21CFR 177.1520 Compliant | - | Yes | |||||||||

| EU directive 10/2011/EC Compliant | - | Yes | |||||||||

| Thickness Range | Micron | 30, 50 | |||||||||

| Corona-Treated Surface | Inside | ||||||||||

| Relative Density | 0.904 | ||||||||||

| Thickness | Micron | 30 | 50 | 30 | |||||||

| Young's Modulus | MD TD |

JIS K7127 | MPa | 650 620 |

720 700 |

700 690 |

590 570 |

560 550 |

540 530 |

690 650 |

500 900 |

| Haze | JIS K7361 | % | 35 | 12 | 5 | 30 | 59 | 59 | 3 | 6 | |

| Friction Coefficient (EC/n-EC) |

Static Kinetic |

JIS K7125 | 0.4 0.4 |

0.3 0.3 |

0.3 0.3 |

0.6 0.6 |

0.4 0.4 |

0.3 0.4 |

0.2 0.2 |

0.4 0.3 |

|

| Wetting Tension |

EC surface | JIS K6768 | mN/m | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Item | Reference Standards | Unit | CF Film (PE Based) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7601A | 7601C | 7601 EA |

7601 EB |

7601 ED |

GR01 | GR02 | 7603B | 7603MS | ||||

| Peel Type | Cohesive | Cohesive | Interlayer | Interface | ||||||||

| Peel Strength N/15 mm (PP Sheet or Paper PE) |

Weak 11 |

Medium 15 |

Weak to medium 13 |

Medium 15 |

Weak 11 |

Medium 15 |

Weak to medium 13 |

Medium 16 |

Medium 17 |

|||

| Adherend | PP, PE | PE, paper PE | PP, PE | Various | ||||||||

| Heat Resistance | Up to 100°C | Up to 100°C | Up to 100°C | Up to 85°C | ||||||||

| Suitable for Retort | No | No | No | No | ||||||||

| Suitable for DL | Yes | Yes | Yes | Yes | ||||||||

| Suitable for EL | Yes | Yes | Yes | Yes | ||||||||

| FDA 21CFR 177.1520 Compliant | - | Yes | Yes | - | ||||||||

| EU directive 10/2011/EC Compliant | - | Yes | Yes | - | ||||||||

| Thickness Range | Micron | 30, 50 | ||||||||||

| Corona-Treated Surface | Inside | |||||||||||

| Relative Density | 0.94 | |||||||||||

| Thickness | Micron | 30 | 50 | 30 | ||||||||

| Young's Modulus | MD TD |

JIS K7127 | MPa | 400 510 |

330 410 |

350 440 |

360 450 |

340 410 |

270 280 |

230 230 |

260 340 |

300 380 |

| Haze | JIS K7361 | % | 57 | 26 | 21 | 17 | 31 | 11 | 15 | 10 | 19 | |

| Friction Coefficient (EC/n-EC) |

Static Kinetic |

JIS K7125 | 0.8 0.8 |

0.9 0.8 |

0.6 0.6 |

0.6 0.6 |

0.5 0.5 |

0.5 0.4 |

0.5 0.5 |

0.1 0.1 |

0.1 0.1 |

|

| Wetting Tension | EC surface | JIS K6768 | mN/m | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |